Let us go to work for you!

The goal of every service we offer is to help our customers be more successful. Allow us to help you increase your output without increasing your overhead.

Surfacing:

All of our locations have 36" Cemco® planer/sanders for both knife planed and sanded finishes. Our Sherwood location has a 50" Cemco® sander for those times a wide sander is needed.

Ripping:

Each facility has ripping capabilities. We can straight line one edge or multi-rip for your specific widths.

Moulding:

We maintain a large inventory of the most common mouldings at all of our stores. With an ever expanding array of knife patterns or making new knives specifically for your application, custom runs are produced with short lead times.

Re-Sawing:

When you need thin stock or when re-sawing will improve your yield, we can provide you this service using our versatile Baker® thin-kerf band re-saw.

Custom Gluing:

Custom face glued butcher blocks and edge glued table tops or panels are made in house to your specifications up to 6" thick, 50" wide and 16' long.

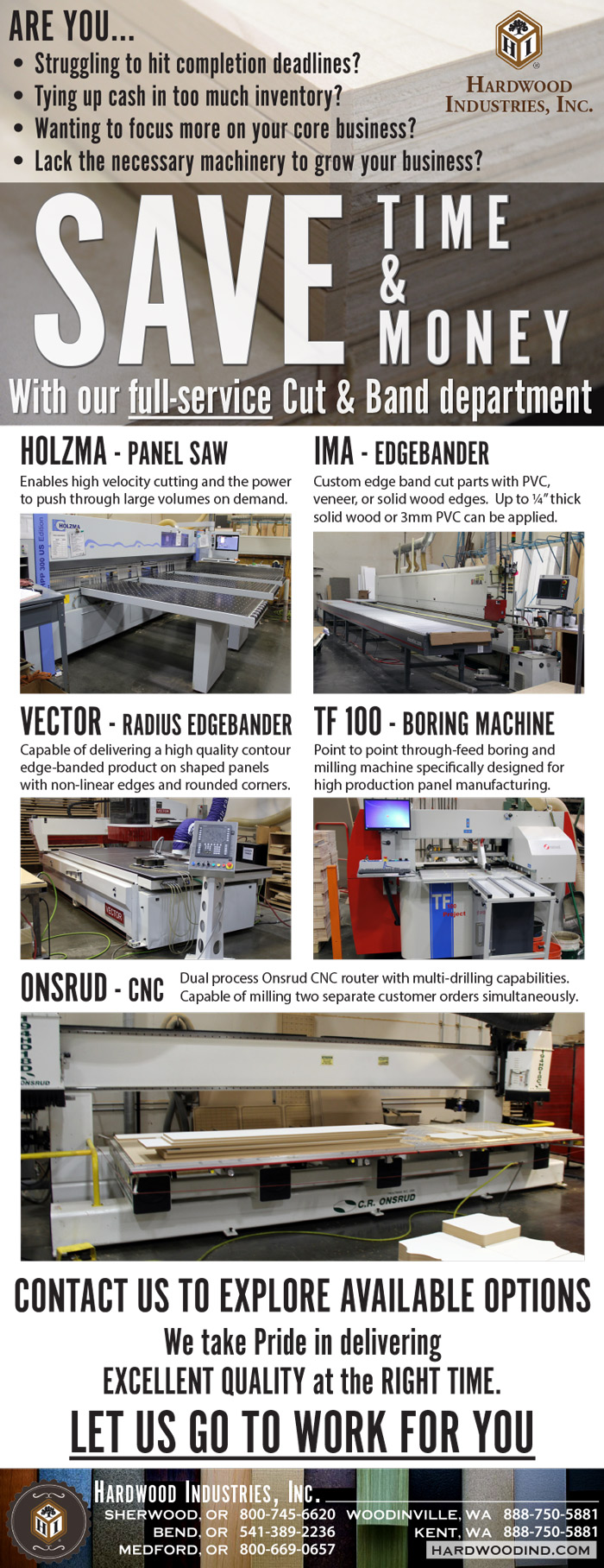

Panel Cutting:

Maximize your yield! Save time and have your sheet stock ordered from us cut with our Schelling® computerized beam saw and optimizing software.

Edgebanding:

Custom edge band your cut parts with Zero-Line, PVC, veneer, or solid wood edges. Up to 1/4" thick solid wood or 3mm PVC can be applied.

ZERO-LINE edge banding now available!

Chopping:

Have us precision end trim your parts to within .007" +/- tolerance when exact measurements are required or chop for yield to the lengths and clarity you desire.

Boring & Machining:

We can provide you with inline boring and custom shaped parts using our Weeke® point to point router.

CNC:

Dual process Onsrud CNC router with multi-drilling capabilities. Capable of milling 2 separate customer orders simultaneously.